As a fermented beverage, beer requires four main ingredients: barley malt, hops, yeast, and water. Beer equipment serves the brewing process of beer. The manufacturing of beer equipment should follow and meet the basic requirements of beer brewing technology.

Beer brewing equipment is generally divided into:

1. Malt crushing system.

2. Glycation system.

3. Fermented sake system.

4. Refrigeration system.

5. CIP cleaning system.

6. Control system,

7. Filling equipment,

8. Steam, air pressure and other auxiliary systems.

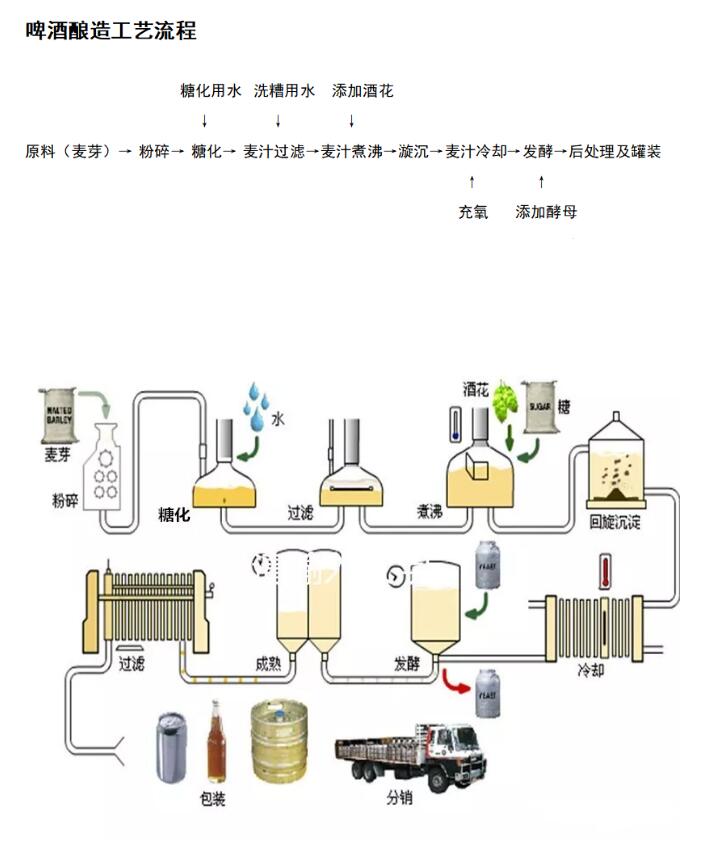

Introduce the technical requirements for beer brewing and equipment configuration based on the beer brewing process flow. Let's first briefly introduce the process of beer brewing. The equipment is checked in place (the tank is cleaned thoroughly and the equipment is operating normally) and meets the brewing conditions. The raw materials (malt, hops, yeast, water) are in place.

1、 Malt crushing system

Malt crushing is for the better dissolution of substances in malt. Malt breaks but does not break, and wheat husk serves as a filter layer for wort filtration.

The crushing system mainly consists of a malt crusher, malt storage and feeding equipment. Small equipment can only be equipped with a malt crusher. The shredders equipped with small and medium-sized beer equipment are generally stick shredders, while large equipment is equipped with four or five roll shredders.

Crushing can be divided into dry powder and wet powder. Small and medium-sized beer equipment generally uses dry powder.

2、 Saccharification system

The saccharification system is the core of the entire equipment for brewing, which is responsible for the process of making malt into wort. Namely, there are four main process steps: "saccharification filtration boiling sedimentation". These four functional steps are completed by several cans, known as "several vessel saccharification". A hot water boiler is an auxiliary equipment.

Each function is implemented using a separate jar, and the four jar saccharification equipment is called the four vessel saccharification. The implementation of four functions using three jars is called "three vessel saccharification". Using two jars to achieve a simple saccharification combination is called: two jars saccharification (saccharification pot filter tank, boiling vortex settling pot).

The main types of saccharification systems for small and medium-sized beer equipment are:

Two devices for saccharification (saccharification filter tank+boiling vortex settling pot);

Two cans and three vessels of saccharification (saccharification filtration tank - vortex sedimentation tank+boiling pot);

Two devices (saccharification filtration tank+boiling vortex settling pot)+hot water pot;

Three equipment saccharification (saccharification pot+filter tank+boiling vortex settling pot)+hot water pot;

Four equipment saccharification (saccharification pot+filter tank+boiling pot+vortex settling tank)+hot water pot.

When choosing to purchase beer equipment, the type, configuration, and size of saccharification used are determined based on the site conditions, brewing process requirements, and yield batch requirements. Simultaneously consider investment costs.

The four main process steps of wort preparation are "saccharification filtration boiling sedimentation". Saccharification refers to the conversion of insoluble substances (starch, cellulose, some high molecular proteins, etc.) in malt into water-soluble substances (sugars, dextrins, minerals, and certain proteins), filtration to obtain clear wort, boiling, and swirling to form a fixed wort.